Materials Performance Testing

Materials Performance Testing

Materials Performance Testing is performed to understand corrosion and materials degradation resistance of a variety of materials. Our wide range of testing equipment allows NCERCAMP researchers to accelerate corrosion processes while testing a material's mechanical properties and its performance in high-temperature environments.

Accelerated Testing

- Expose coated and uncoated panels to aggressive environments to analyze corrosion resistance

- Accelerate damage and predict the material’s performance

- Material degradation/corrosion processes are accelerated significantly under extreme environmental conditions

- Tests simulate effects of sunlight, dew and rain, generating weathering data in a few weeks or months

- Performance of metals, polymers and coatings for damage including color change, gloss loss, chalking, cracking, crazing, hazing, blistering, embrittlement, strength loss and oxidation

Mechanical Testing

- Evaluate electrochemical, physical and mechanical properties of coatings

- Qualification of hardness of films and coatings of materials varying from polymers to metals

- Determination of coating adhesion to substrate through nanoscratch testing

- Determination of coating failure mechanisms

- Highly localized determination of dynamic mechanical properties

- New techniques for testing reliability of commercial alloys

- Fatigue crack growth, high-cycle fatigue, low-cycle fatigue, fracture toughness, tension and compression

High-Temperature Testing

- Simulate operating stresses experienced in a pressurized water reactor system that is complete computerized

- High-temperature, high-velocity (up to Mach 2) burner rig testing with capability for sand ingestion

- Stressed oxidation testing under high-velocity, high-water-content atmosphere up to 1450°C

- Thermal-barrier-coated (TBC) superalloy system and ceramic matrix composite evaluation

- Understand influence of temperature on structure of metal

- Continuous measurement of oxidation kinetics as well as change in metal structure

- Heat treatments of materials in wide range of atmospheres and temperatures

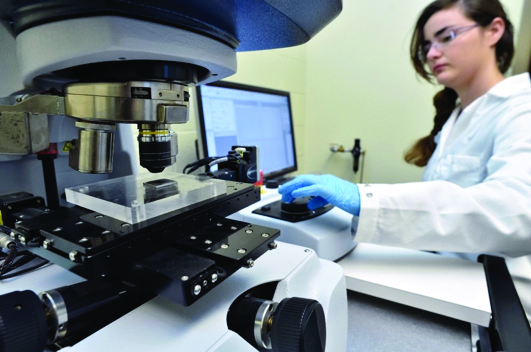

A Corrosion Engineering student performs hardness testing on a micro-indenter.

Contact NCERCAMP

Address

264 Wolf Ledges Parkway

Akron, Ohio 44325

Telephone

Office: 330-972-6978

Fax: 330-972-5141